Aivison

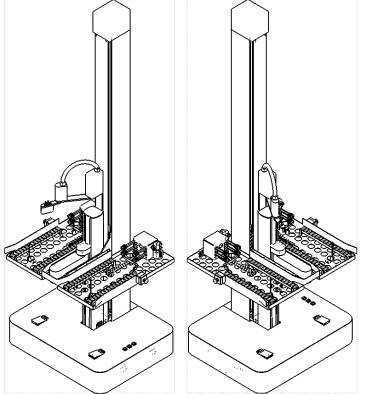

Composite Robot

- Quick Configuration, Ready to Use;

- Highly flexible and adaptable to production;

- Multiple checks for safety and accuracy;

- Customization support, flexible and user-friendly.

One-Stop Vehicle Manufacturing Solution

Aivison has launched a one-stop vehicle manufacturing solution that focuses on centralized supply, addressing the challenges of component selection for vehicle manufacturing. This provides strong support for companies to create efficient, stable, and reliable mobile robots.

based on B -150 /300

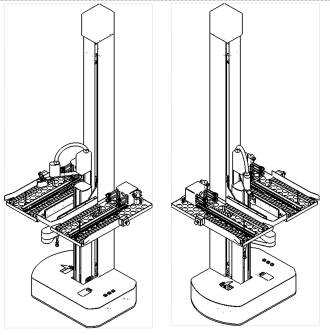

Robotic Arm Component

Collaborative mobile robots with robotic arms are a major trend in future market development. In industries such as 3C electronics, semiconductors, and healthcare, collaborative robots provide innovative solutions.

Aivison offers high-precision laser SLAM navigation positioning, equipped with industrial cameras, ensuring 2D accuracy of ±0.5mm and 3D operational accuracy of ±1mm.

based on B -300S(CE)

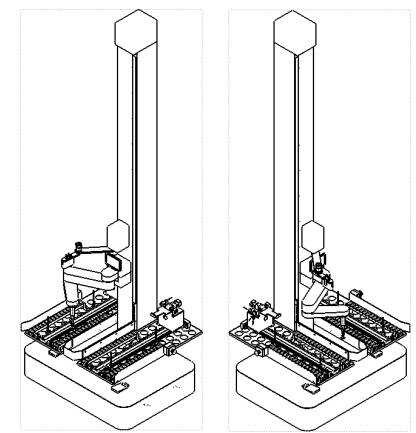

Roller Component

Rollers are common conveyor devices in automated factories. When goods on the rollers need to be transferred, mobile robots equipped with roller components become effective assistants, ensuring smooth and efficient production processes.

The component can be secured to the B-300S(CE) with just 6 bolts, connecting to the reserved interface on the chassis for easy hardware assembly. It supports custom roller group docking heights to meet the weight handling requirements of most roller scenarios. Equipped with three sets of non-contact photoelectric sensors, it ensures the safety of material transfers and the accuracy of position detection.

based on B -300S(CE)

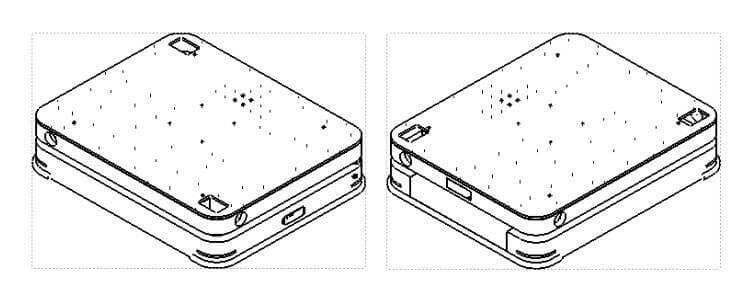

Lifting Component

During the transportation process on production lines, scenarios often arise with inconsistent docking heights. The lifting component can be easily added to the chassis to solve height issues, with the ability to adjust the lifting height based on different docking requirements, ensuring flexibility and safety during cargo transfer.

It can be fixed to the B-300S(CE) with just 4 bolts, connecting the wiring of the lifting component to the reserved interface on the chassis for quick hardware assembly. It supports customized lifting heights, catering to various small non-contact handling needs. It also includes an anti-offset design, enhancing its load-bearing capacity and adaptability, ensuring stable rated loads.

Precision, punctuality, safety

AIVISON Intelligent Composite Robot

Dramatically reduce costs and improve handling efficiency

Simple Setup

AMR chassis with pre-installed interfaces for easy structural assembly

Highly flexible

Flexible shuttle between production lines, automatic obstacle avoidance, flexible scheduling

Safety and Accuracy

Multiple sensor protection for safety and reliability

Multiple checks

Optical sensing to ensure accurate material positioning

Ready to Use

Complete system configuration via Roboshop and you’re ready to go!

Strong adaptability

Suitable for a variety of industries such as 3C electronics, logistics and express delivery, semiconductor and healthcare

Case Studies:

Related products

If you have any qustions, feel free to reach out and we’ll respond as soon as possible.