Exploring AMR

Together

Cost Savings and Efficiency

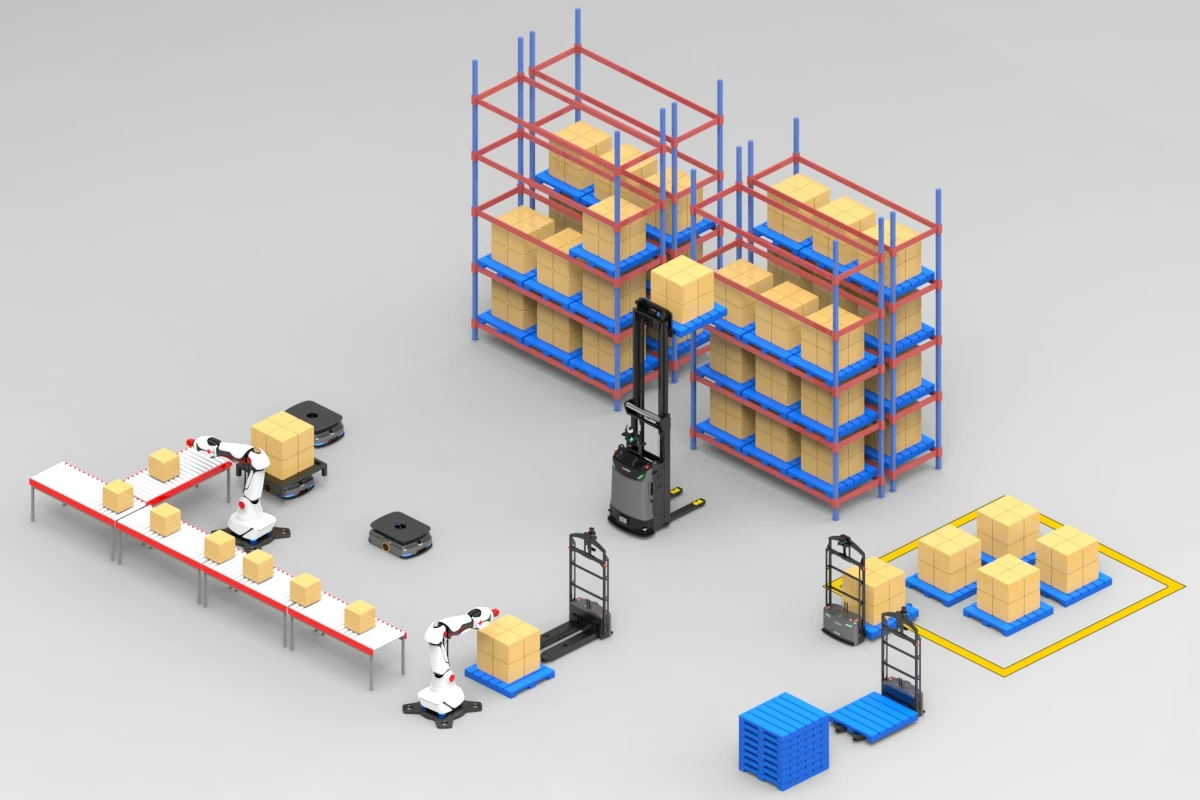

With autonomous navigation, automated material handling and transportation, the AMR replaces manual operations, integrates precisely into various production processes and adapts to different working environments.

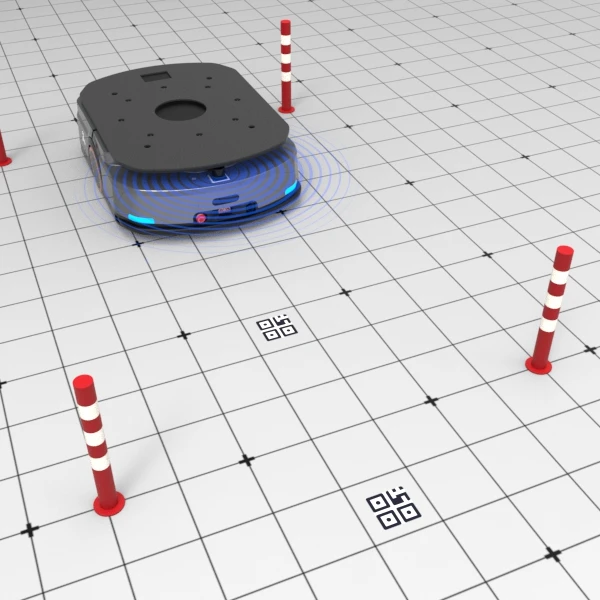

Navigation Mode

Aivison’s AMR vehicles are typically equipped with laser radar, using advanced laser SLAM navigation for high precision and strong anti-interference capabilities. In some cases, when the environment changes dynamically and significantly impacts the AMR’s movement path, QR code or reflective plate-assisted navigation systems can be added to enhance stability.

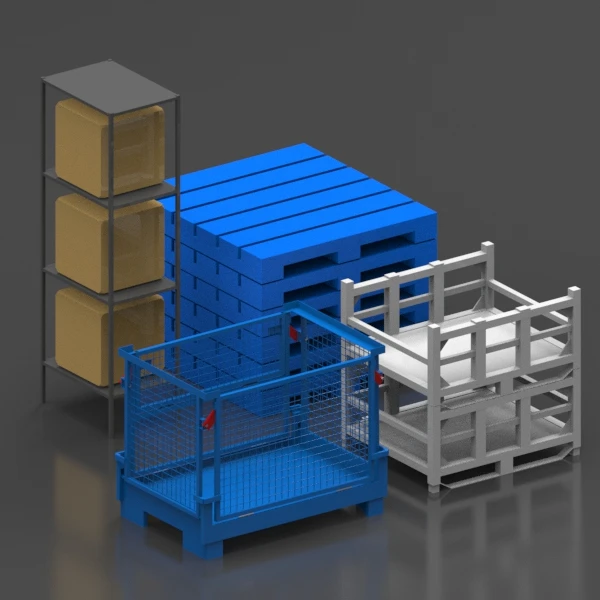

Shelf Standards

During material handling, different types of goods often require different load tools. For example, standardized goods that have regular shapes only need pallets for transport, in which case a forklift-style AMR can easily handle them. For goods of various shapes and sizes, material cages or trolleys may be used, and a latent lifting AMR is the most suitable choice.

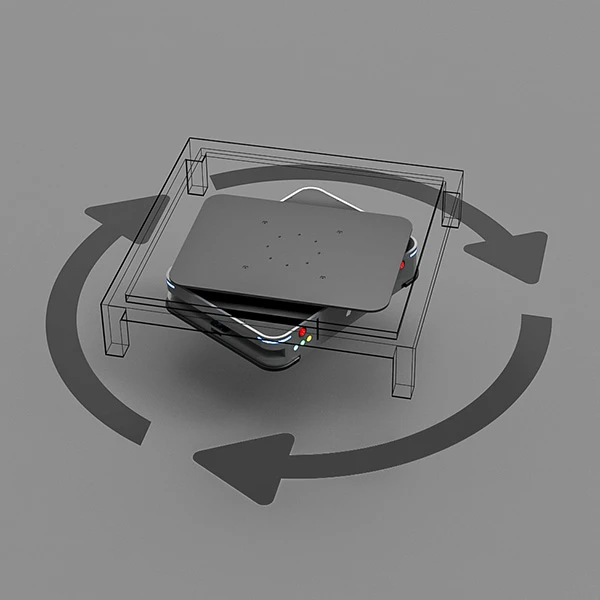

Is Contour Following Required?

In certain production and transportation processes, there are situations where goods need to maintain a constant angle relative to the ground during transport, such as to avoid shaking, meet safety regulations, or achieve precise docking. In such cases, you would need to select a lifting robot with contour-following capabilities for material handling.

Fixed Posture Not Required

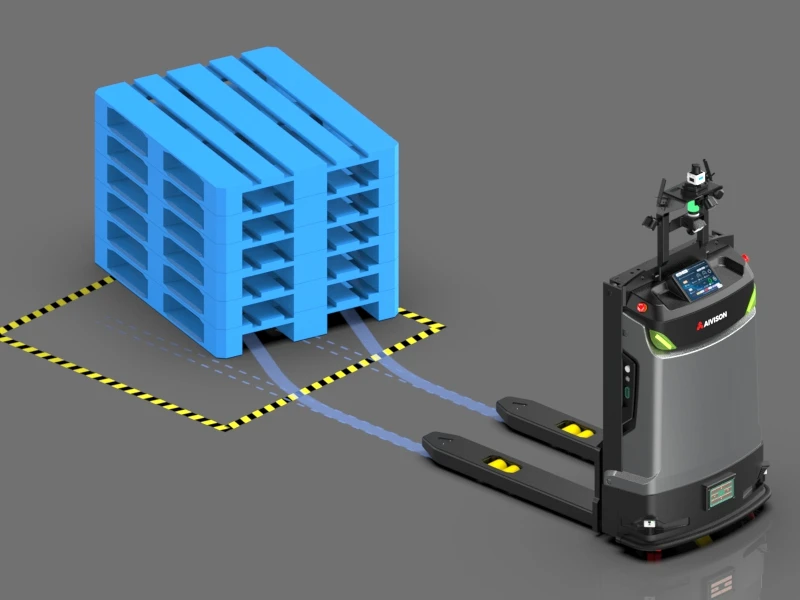

Typically, to maximize space utilization, goods are required to be neatly arranged. However, there may be cases where the requirements are less strict, and during the storage process, shelves or pallets may not have fixed positions, causing their angles to be unstable. In this case, the AMR needs to have rack or pallet recognition capabilities. The AMR can be equipped with a 3D camera with laser or pallet recognition to automatically identify racks or pallets and adjust the vehicle’s position accordingly.

Pallet Stacking

Smart Forklift trucks can realize highly accurate positioning, gripping, moving and multi-layer stacking of pallets, cages, etc. with a positioning accuracy of ±10mm through the synergy of 3D cameras and algorithms.

Multi-Robot Collaboration

In larger-scale production processes, there are often multiple tasks with different requirements, such as material handling, retrieval, stacking, loading/unloading, and packaging, which require different types of AMRs to work collaboratively. Through Aivison’s RDS unified resource scheduling system, precise multi-robot collaboration can be achieved.

If you have any qustions, feel free to reach out and we’ll respond as soon as possible.