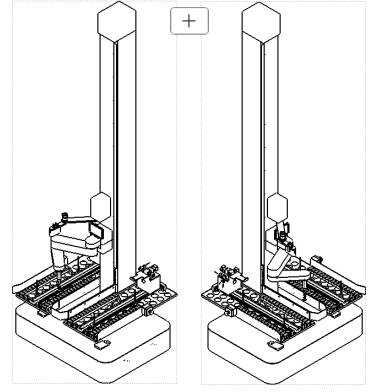

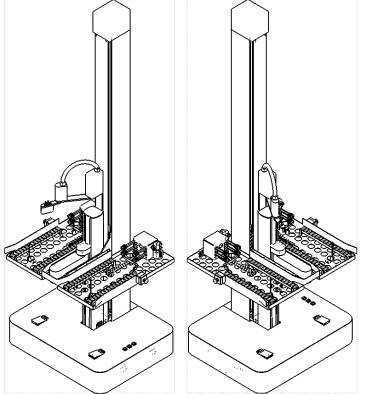

ER.200.4b Lifting Platform Constructor Kit

Product Overview

The Mobile Platform Constructor KitcER.200.4b is a specialized autonomous warehouse robot designed for order picking, collection operations, goods sorting, and shelf-mounted box/crate handling.

Key Technical Specifications

|

Parameter |

Specification |

|

Maximum Payload Capacity (per item) |

2.0 kg |

|

Maximum Total Platform Load |

50 kg |

|

Maximum Speed (unloaded) |

1.5 m/s |

|

Maximum Speed (loaded) |

1.2 m/s |

|

Overall Dimensions (H × W × D) |

3506 × 1258 × 1009 mm |

|

Operating Weight (with battery) |

172 kg |

|

Turning Radius |

1.2 m |

|

Operating Temperature Range |

5°C to 40°C |

|

IP Protection Rating |

IP52 |

Components NOT Included in Delivery

- Central Computer System NOT Included

Specification Required:

- Industrial-grade embedded computer or single-board computer (SBC)

- Minimum specifications: Multi-core processor (ARM or x86), 8GB RAM, 128GB storage

- Operating system compatible with warehouse management system (WMS) integration

- Environmental rating suitable for warehouse conditions (operating temperature: 5-40°C)

- Mounting brackets and electrical connections compatible with robot power system

- Radio-Electronic Equipment NOT included

The constructor kit is supplied as a mechanical and propulsion system only. All radio-electronic navigation and communication equipment must be procured separately.

Required Radio-Electronic Components (NOT Included)

2.1 Wireless Communication Modules

- Wi-Fi Module:Industrial-grade 802.11ac/ax wireless module for warehouse network connectivity

- Bluetooth Module:Bluetooth 5.0 or higher for local device communication and diagnostics

- Specifications Required:Operating frequency compatible with local regulations, industrial temperature rating (-20°C to +60°C)

2.2 LiDAR Navigation System

- Type:2D or 3D laser distance measurement and mapping system

- Range:Minimum 20-meter detection range

- Accuracy:±30 mm or better

- Scanning Frequency:Minimum 10 Hz

- Mounting:Forward-facing primary sensor; optional rear-facing sensor for enhanced safety

2.3 Additional Sensors

- Vision cameras for shelf scanning and item verification

- Proximity sensors for fine positioning and collision avoidance

- Ultrasonic sensors for supplementary obstacle detection

- IMU (Inertial Measurement Unit) for motion tracking

Included Components (Standard Delivery)

The Mobile Platform Constructor Kit includes comprehensive mechanical, structural, and safety components:

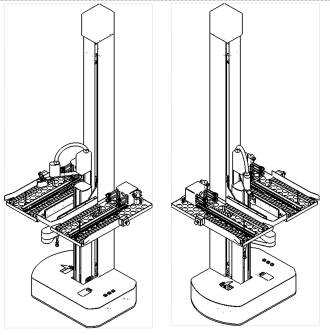

Structural Components

- Robot Main Frame/Chassis: Structural base assembly (3388 mm H × 1258 mm W × 1009 mm D)

- V-Belt Lifting Mechanism: Vertical mast with V-belt driven carriage (maximum lifting height: 3000 mm)

- Lifting Carriage Assembly: Mobile carriage traveling on precision guide rails

- Guide Rails: Precision rails for smooth vertical guidance

- Load Attachment Interface: Mechanical coupling for baskets/containers (maximum payload: 50 kg)

Pneumatic System

- Vacuum Pump: Pneumatic pump (40V supply, 140 l/min capacity)

- Manual Grippers: Attachment grippers (up to 30 kg capacity, one side only)

- Basket Extraction Actuators: Pneumatic cylinders for gripper control

- Vacuum Hose Assembly: Tubing with pressure regulators and control valves

- Vacuum Pump Power Supply Module: Dedicated 40V electrical module

Manipulator System

- 4-Axis Manipulator Arm: Multi-axis robotic arm for precise item positioning

- Manipulator Joint 1 (Base/Waist): Primary rotational joint for horizontal positioning

- Manipulator Joint 2 (Shoulder): Vertical/shoulder articulation axis

- Manipulator Joint 3 (Elbow): Elbow flexion for precise reach

- Manipulator Joint 4 (Wrist): Wrist rotation (maximum payload: 3 kg)

- End Effector Interface: Quick-change coupling for grippers/vacuum cups/tools

- Motor Drives: Servo or stepper motors for each joint axis

- Control Electronics: Local controller (maximum lifting height: 800 mm)

- Feedback Sensors: Encoders and position sensors for closed-loop control

Crate Handling System

- Hook Mechanism Assembly: Specialized hook-and-latch mechanism for crate retrieval

- Fixation Brackets: Positive fixture system for secure crate mounting

- Engagement Detection Sensor: Confirmation of proper hook seating

- Stability Monitoring System: Real-time verification of crate fixation integrity

Electrical and Safety Systems

- Main Power Supply Unit: Central electrical power distribution

- Power Distribution Board: Circuit breakers, relays, and distribution terminals

- Emergency Stop System: Safety-critical circuit for immediate power cut

- Safety Interlocks: Mechanical and electrical safety devices

- Wired Communication Interface: Standard Ethernet or proprietary connection for WMS integration

- Control Panel/Operator Interface: Physical or software interface for system monitoring

- Lighting Module: LED illumination for consistent vision system performance

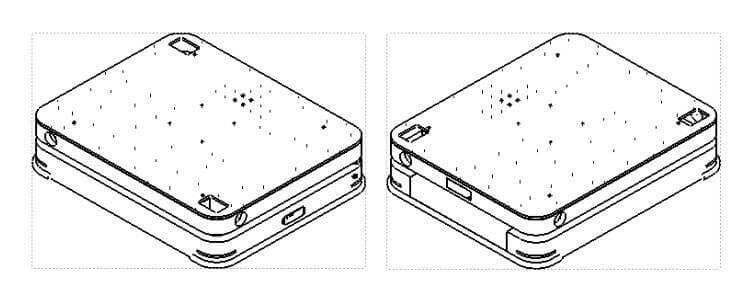

Mechanical Support

- Mounting Feet/Base Stabilizers: Stable positioning with leveling adjustments

- Lubrication System: Maintenance points and lubricant distribution

Related products

-

Composite Robot

Laser SLAM Handling Autonomous Forklift

The Strongest Forktlift, Flexible and Efficient

If you have any qustions, feel free to reach out and we’ll respond as soon as possible.