Laser SLAM

Stacker Autonomous Forklift

- Dual-Mode Flexibility

- Precision Stacking

- Scalable Compatibility

- Safety Assurance

FD-1500L

1500 kg

Rated load capacity

600 mm

Load center distance

3300 mm

Standard lifting height

Open pallet

Pallet type

Hybrid Flexibility

1500kg Payload Capacity

Engineered for heavy-duty stacking, the FD-1500L handles loads up to 1500kg while maintaining stability at a 600mm load center distance, ensuring safe lifting and transport in high-rack warehouses.

Hybrid Flexibility

Hybrid 360° Laser SLAM Navigation

Equipped with 4 laser radar (LiDAR) units (top, dual-side bottom, rear base), the AMR achieves centimeter-level positioning accuracy and omnidirectional obstacle detection. Operate seamlessly in auto-navigation mode for predefined routes or manually via a handheld remote controller for adaptive scenarios.

Precision, punctuality, safety

Laser SLAM Autonomous Pallet Truck

Dramatically reduce costs and improve handling efficiency

1.5 T Load Capacity, Stacking Height up to 3 m

Featuring a mainstream 1.5 tons load capacity, this premium Linde model reaches stacking heights of up to 3 meters. With a vehicle width of just 1128 mm and a minimum turning radius of only 1329 mm, it navigates effortlessly through narrow aisles.

Flexible Customization, Advanced Stacking Capability

With customizable fork heights of 2344 mm, 2924 mm, and 3244 mm, offering multi-level stacking and destacking capabilities. Supports customizable fork widths of 555 mm, 600 mm, and 680 mm, optional features include various laser navigation and 3D obstacle avoidance functions, and customization with your

company’s logo.

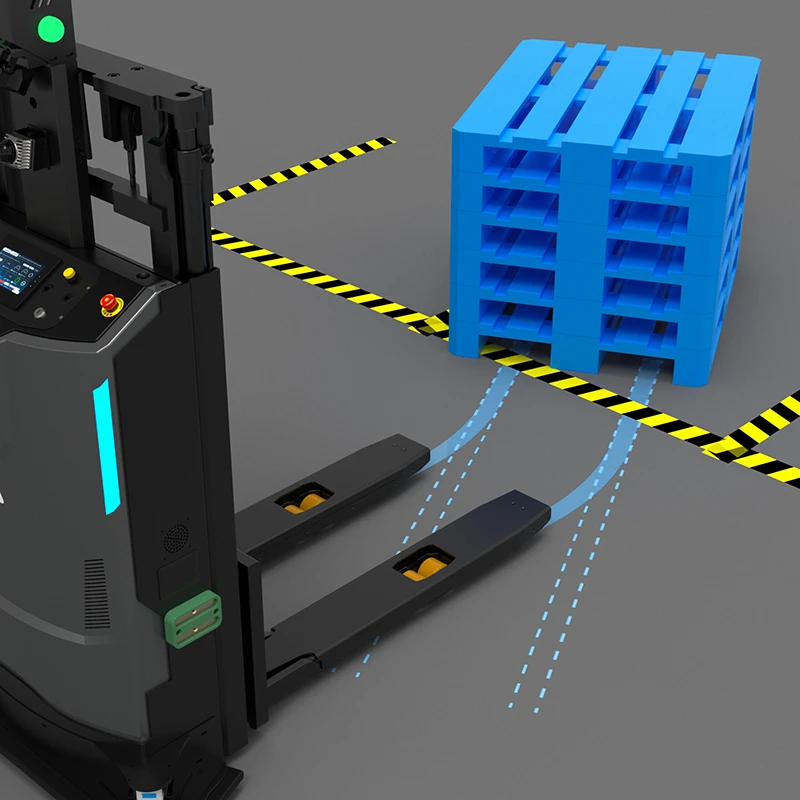

3D Obstacle Avoidance, 360° Safety Protection

Equipped with a 3D obstacle avoidance camera, capable of scanning objects within 0.2 m to 5 m range and measuring depth data within that range, ensuring heightened,safety.

AI Deep Learning, Improved Recognition Ability

It boasts the capability to recognize pallets, racks and cages in different colors and sizes with unparalleled precision and adaptability from multiple angles. Experience seamless and stable handling and transfer of goods.

10 h Endurance, 3-min Fast Battery Swap

Equipped with a 24 V / 212 Ah battery, providing up to 10 hours of continuous operation. Supports rapid battery replacement within 3 minutes for added convenience.

Hybrid Flexibility

Intelligent Pallet Recognition

Pallet Recognition refers to the system’s ability to automatically detect pallet positions and angles using integrated sensors, enabling:

- Auto-alignment: Adjusts fork positioning without manual intervention.

- Error Reduction: Minimizes misalignment risks during high stacking.

- Operational Speed: Accelerates docking cycles by 30% compared to traditional forklifts.

Hybrid Flexibility

High-Efficiency Stacking & Customizable Forks

- Stacking Height: 2430mm or 3300mm for multi-tiered rack access.

- Adjustable Fork Width: 555mm / 600mm / 680mm to diverse pallet standards (e.g., EUR-pallets, industrial blocks).

Typical Use Cases: - Dense high-bay warehouses requiring vertical storage optimization.

- Production line feeding with varying pallet sizes (e.g., automotive parts).

- Cold chain logistics with rapid loading/unloading from multi-level racks.

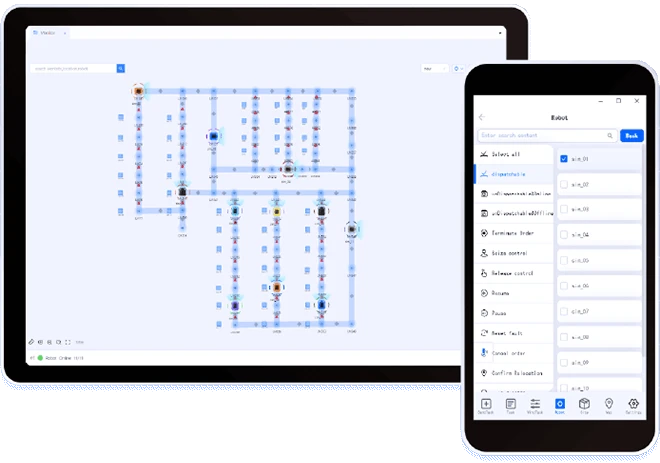

Fleet Management System

manage dispatching system for mobile robots and factory automation logistics equipment in a unified manner.

Get Rid of Empty Load Anxiety

Consider Hitchhiking and Pre-order Task Dispatching

High Adaptation

Dynamic Global Collaborative Planning

What You See is What You Operate

Panoramic Business And Scheduling Simulation

Keep Track of The Whole Progress

Visualisation of The Task Process

Intuitive and Simple UI Interaction

Mobile Terminal APP Configu ration Customisation

Easy to Handle

Robot Alert Handling

Parameter Specification

-None ● Standard ○ Optional

| Basic parameters | |

|---|---|

| Product name | Laser SLAM Stacker Autonomous Forklift |

| Operation type | Automatic navigation, by manual control device |

| Navigation type | Laser SLAM |

| Pallet type | Open pallet |

| Rated load capacity | 1500 kg |

| Load center distance | 600 mm |

| Weight (with battery) | 835 kg |

| Standard lifting height | 2430 / 3300 mm |

| Forklift dimensions: L × W × H | 1730 × 1128 × 1964 mm |

| Fork dimensions: L × W × H | 1200 × 185 × 55 mm |

| Fork outer width | 555 / 600 / 680 mm |

| Minimum turning radius | 2025 + 200 mm |

Related products

If you have any qustions, feel free to reach out and we’ll respond as soon as possible.