Laser SLAM

Stacking Smart Forklift AMR

- Heavy Load, Smarter Stackin

- Error-Proof Pallet Handling

- Future-Proof Flexibility

- Space Optimization

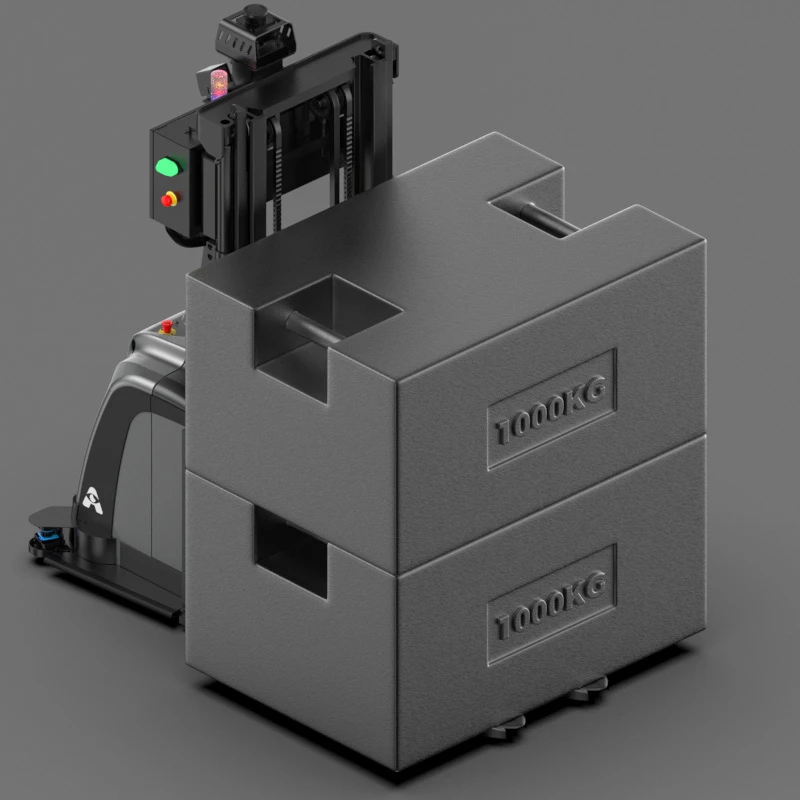

FD-2000

Smaller size, smarter algorithms!

2000 kg

Rated load capacity

600 mm

Load center distance

3000 mm

Standard lifting height

Open pallet

Pallet type

Hybrid Flexibility

2000kg Payload for Heavy-Duty Stacking

- Industrial-Grade Capacity: Designed to handle 2-ton loads (e.g., steel coils, machinery parts, building materials), addressing inefficiencies in traditional forklifts struggling with heavy or irregularly shaped goods.

- Targeted Pain Points: Reduces reliance on labor-intensive manual stacking in industries like heavy manufacturing, bulk logistics, and construction, where payload limitations often delay workflows.

Hybrid Flexibility

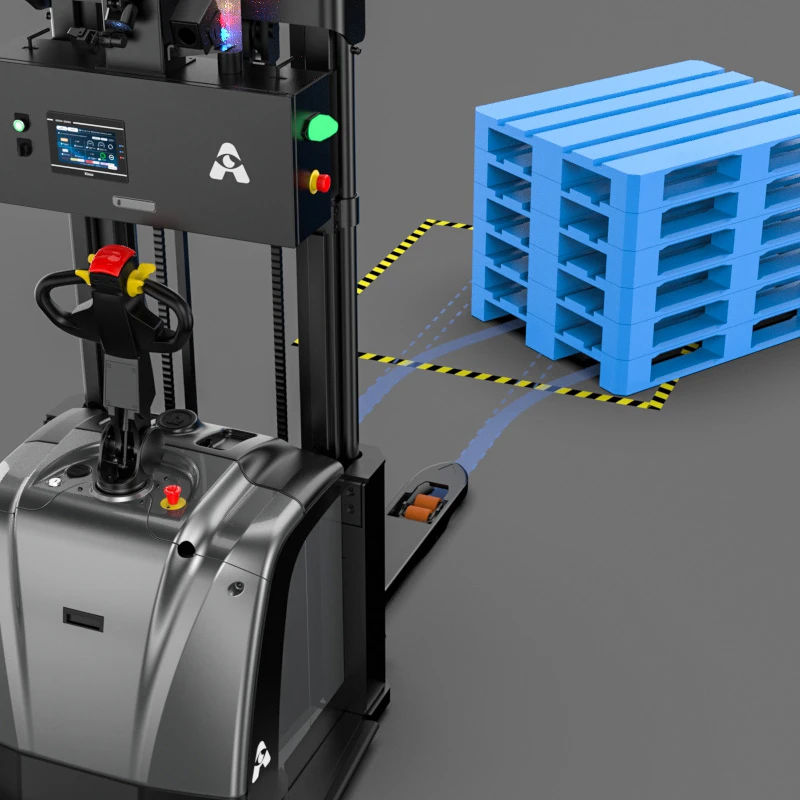

Laser SLAM Navigation & Omni-Directional Safety

- Autonomous Precision: Laser SLAM ensures real-time mapping and obstacle avoidance (±5cm accuracy), paired with 360° collision sensors for robust safety in high-traffic zones.

- Agile Maneuverability: 1737mm minimum turning radius enables efficient operation in ultra-narrow aisles (2.2m clearance) and compact storage layouts (e.g., multi-level racking systems).

Precision, punctuality, safety

Laser SLAM Stacker Automatic Forklift

Dramatically reduce costs and improve handling efficiency

Comprehensive Protection

Obstacle avoidance laser+Bumper+Distance sensor+3D Camera-360° protection.

Good Applicability

Ramp, gap, elevator, transfer, stacker.

Heavy Load

Rated loads up to 2000kg.

Real Laser SLAM

Easy to deploy with trackless route navigation.

Automatic Charging

Support automatic charging without staff.

Customizable Lifting Stroke

Up to 6M.

Hybrid Flexibility

Seamless Manual/Automatic Mode Switching

- Why Manual Mode?: Retains manual override via integrated ergonomic handle for:

- Emergency interventions (e.g., navigating unforeseen obstacles).

- Fine adjustments in precision stacking tasks.

- Gradual workforce transition, allowing operators to adapt to AMR workflows without disrupting operations.

- Adaptive Use Cases: Hybrid factories, legacy warehouses upgrading to automation, and facilities requiring flexible task reassignment.

Hybrid Flexibility

AI-Powered Pallet Recognition

- 3D Vision + Machine Learning: Automatically scans and corrects misaligned pallets (e.g., staggered positioning or tilted placement) using onboard 3D cameras and AI algorithms.

- Scenario Benefits: Eliminates manual repositioning in high-throughput e-commerce warehouses, automotive part storage, or food/beverage distribution, minimizing load shifts and product damage.

Parameter Specification

-None ● Standard ○ Optional

| Basic parameters | |

|---|---|

| Product name | Laser SLAM Stacker Autonomous Forklift |

| Operation type | Automatic navigation, walk-behind driving |

| Navigation type | Laser SLAM |

| Pallet type | Open pallet |

| Rated load capacity | 2000 kg |

| Load center distance | 600 mm |

| Weight (with battery) | 1230 kg |

| Standard lifting height | 3000 mm |

| Forklift dimensions: L × W × H | 2190 × 1064 × 2200 mm |

| Fork dimensions: L × W × H | 1150 × 180 × 55 mm |

| Fork outer width | 570 / 680 mm |

| Minimum turning radius | 1737 mm |

Related products

Contact Us

If you have any qustions, feel free to reach out and we’ll respond as soon as possible.